Machine-Type: M0620

Ultrasonic cutting

Working width:

Type 1:

40cm - 140cm

Type of material to cut:

flat

Consisting of the following modules:

- Base frame

- Extractor with dancer system

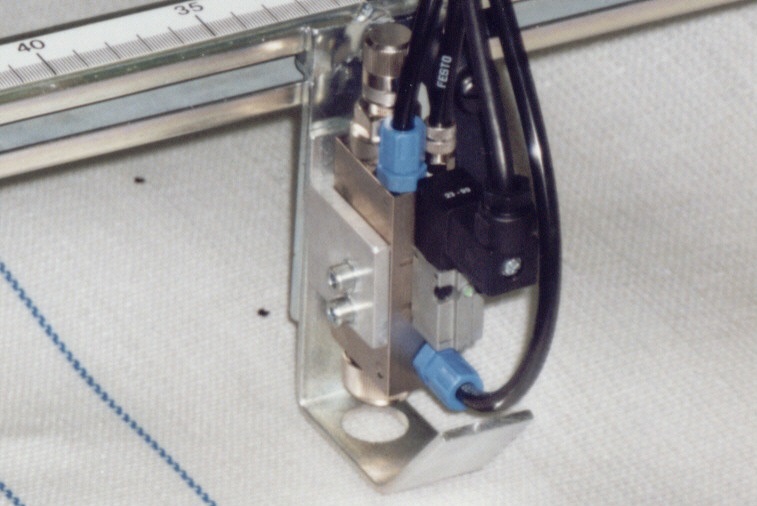

- Circle cutter with ultrasonic cutting head (thermal cutting)

- Transport roller system with length measuring device

- Cross cutter with ultrasonic cutting head. (thermal cutting)

Cutting shapes:

Options:

Description:

Ultrasonic cross and circle cutting machine for the production of high-quality BIG-BAGs. With the ultrasonic cutting system, coated and uncoated material can be cut. The cutting edges are thermally sealed, a beading at the cutting edges is excluded during ultrasonic cutting. In conventional hot cutting systems, suction devices are required for the resulting cutting vapors; these are not necessary during ultrasonic cutting. The circle cutter can be adjusted from 200 mm to 590 mm to any diameter. The programmable work data, which refer to the respective material, can be stored in an optional recipe program and reactivated by simply pressing a key combination. All electronic machine parameters can also be saved via the control panel.

Detailed Options:

Mobile material cart

This trolley consists of a steel frame and four swivel castors, two of which are equipped with a brake. In addition, the car has a material receiving rod with two lateral Bergrenzungsscheiben or two cones.

Lifting devices without edge control

The device is a cost-effective alternative to our V3130 edge control hoist. In our experience, most of the fabric roll is now straight-edged. Even if small displacements occur on the fabric rolls, our machines still have a centrally extending material web. It can roles, as with the model V3130 to max. 1000 kg are lifted. The pickup bar for the material rolls is equipped with two aluminum rings, which serve for lateral fixation of the rolls. The applied brake band reduces the running of the roller during a stop.

Lifting devices with edge control

This lifting device with edge control, model V3130, can handle material rolls up to max. Lift 1000 kg. Next, the station with a receiving rod and two rings, which serve for lateral fixation of the rollers, stocked. A product edge is constantly scanned during the run over 2 photocells and automatically corrected by the integrated actuator when the goods are running. The material web therefore always enters a defined position in the subsequent machine. The applied brake band reduces the running of the roller during a stop.

Line and dot marking system with pen

V2001-02 Inexpensive marking device with pen holders and rail system for applying lines and / or dots. When marking points, the material flow stops for a short time and the pen is lowered onto the material.

4-point marking system with pen

V2002-4P Inexpensive marking device with four pen holders for marking 4 points. The pen holders can be adjusted with an adjustable cross to the respective size. If a circle or shape cutter is used, the dots are applied at the same time as the blank.

Fast marking system with spray head

This marking system applies dots and lines without stopping the material. This system can be integrated into almost all types of machines as it uses its own control electronics. The system is integrated in a compact frame which also allows installation in third-party systems.

Slitter with ultrasound (hot cutting)

For separating synthetic fabrics when a smaller width of material or center cut is needed. The cut edge is very clean and has no discoloration or beading of the material. In addition, the edge is sealed during the cut, which prevents tearing of the fabric edge.

Automatic depositing device with gripper u. Lift table

This depositing system is used when an automatic storage of the blanks is required. The material is taken over by the integrated gripper system behind the cross cutting system and extended to length. Once the length has been reached, the cross-section is made and the material is deposited on the lifting table. The lift table lowers automatically when the cut pile becomes larger.

Stacking table

The storage table consists of a tubular steel frame and table top. On request, this can be ordered with a false floor. The table depth is 100cm. The table width results from the working width of the machine.

Technical data:

| Working width: | 140cm (special sizes on request) |

| Cuttting system: | Ultrasonic cutting |

| Circle cutter: | Ø 200mm – 590mm infinitely adjustable (special sizes on request) |

| Power connection: | 400V / 50Hz |

| Compressed air connection: | approx. 8bar |

| Operating air pressure: | approx. 6bar |