Machine-Type: M0650

Ultrasonic cutting

Working width:

Type 1:

40cm - 140cm

Type of material to cut:

flat

Consisting of the following modules:

- Base frame

- Lifting device with edge control

- Extractor with dancer system

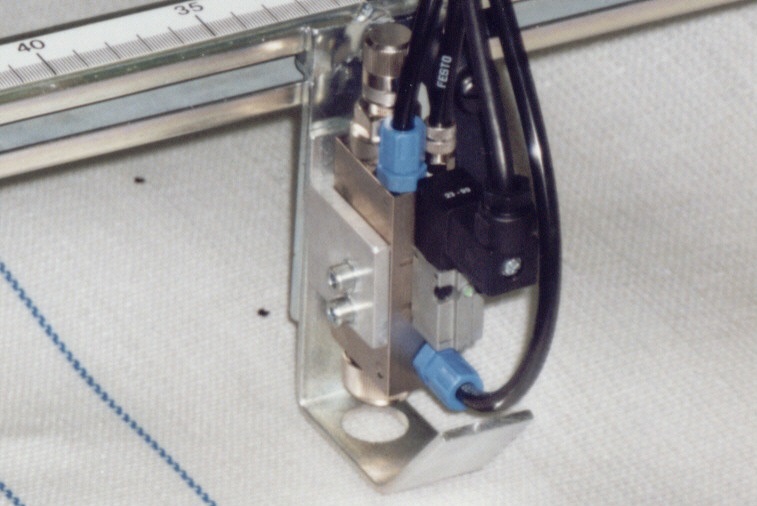

- Circle- and shape cutter with ultrasonic cutting head (thermal cutting)

- Transport roller system with length measuring device

- Cross cutter with ultrasonic cutting head. (thermal cutting)

- Automatic depositing system with gripper and lifting table

Cutting shapes:

Options:

Description:

All cut edges that are located inside a FIBC must be cut absolutely clean and there must be no beads of melt at the cut edges. The inner ring construction of a dimensionally stable FIBC consists of four material sections, which are always equipped with several cutouts. In order to get no residue at exactly these cutouts, but a fusion of the cut edge is guaranteed, only an ultrasonic cutting system can be used and it was exactly for this application, this ultrasonic cutting machine was developed. Since for cost reasons, five ultrasonic cutting heads are used and the individual sections sometimes require up to six mold cutouts, the number of cycles of the system is limited. However, two sections are always cut simultaneously. The directly mounted depositing device with its gripper tongs automates the machine to a large extent. Thus, no operator has to stand extra to the machine. It is sufficient that now and then a person removes the automatically deposited sections of the side of the machine and then stores in a lattice box. The blank data of the different shapes can be stored in the cutting menu and re-activated as needed by a simple key combination. The drives of the system are infinitely variable and thus allow an optimal adaptation of the required goods and cutting speed to the material to be processed. Another advantage is that the system is largely maintenance-free and user-friendly.

Detailed Options:

Line and dot marking system with pen

V2001-02 Inexpensive marking device with pen holders and rail system for applying lines and / or dots. When marking points, the material flow stops for a short time and the pen is lowered onto the material.

Fast marking system with spray head

This marking system applies dots and lines without stopping the material. This system can be integrated into almost all types of machines as it uses its own control electronics. The system is integrated in a compact frame which also allows installation in third-party systems.

Technical data:

| Working width: | 140cm (special sizes on request) |

| Cuttting system: | Ultrasonic cutting |

| Circle cutter: | Ø 300mm |

| Shape cutter: | H x B adjustable up to approx. 200mm |

| Power connection: | 400V / 50Hz |

| Compressed air connection: | approx. 8bar |

| Operating air pressure: | approx. 6bar |